Welding Indium Tin Oxide Coated Glass

Welding Indium Tin Oxide Coated Glass – Ultrasonic Welding – Cheersonic

ITO COATED GLASS (Indium tin oxide coated glass) belongs to the group of TCO (transparent conducting oxide) conductive glasses. An ITO glass has a property of low sheet resistance and high transmittance. It is mostly used in research and development. ITO coated glass substrates are widely used to organic/inorganic heterojunction solar cells, Schottky solar cells, CdTe solar cells and other various thin film solar cells as transparent semiconductor oxide electrode materials since their transparency and high conductivity. Indium tin oxide (ITO) is a ternary composition of indium, tin and oxygen in varying proportions. Depending on the oxygen content, it can either be described as a ceramic or alloy. Indium tin oxide is typically encountered as an oxygen-saturated composition with a formulation of 74% In, 18% O₂, and 8% Sn by weight. Oxygen-saturated compositions are so typical, that unsaturated compositions are termed oxygen-deficient ITO. It is transparent and colorless in thin layers, while in bulk form it is yellowish to grey. In the infrared region of the spectrum it acts as a metal-like mirror.

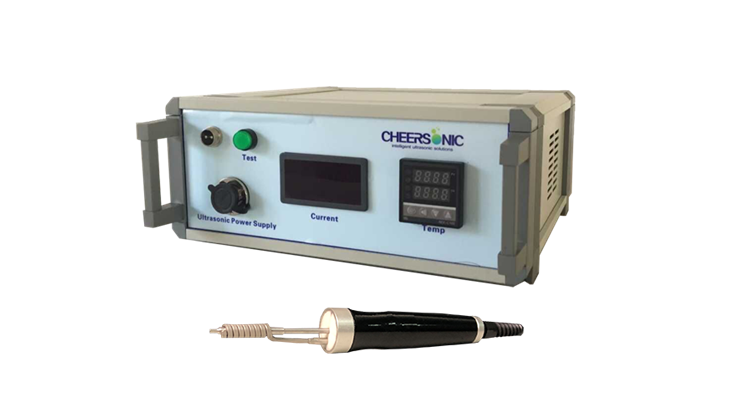

The tip of ultrasonic soldering iron vibrates at ultrasonic frequencies. This vibration induces cavitation in the molten solder, which breaks up and removes oxides and promotes wetting. Ultrasonic soldering iron enables the easier joining of hard-to-solder materials which are known as impossible or difficult to be soldered in conventional soldering. Eco-friendly soldering is achieved by fluxless soldering and no post treatment to remove flux. The ultrasonic soldering technology is widely used in ITO coated glass. The ultrasonic soldering iron of Cheersonic produces high quality soldered joints. Using the solder alloy, can easily solder directly to glass, ceramics and other low solderability materials.

Cheersonic is an expert manufacturer of ultrasonic equipment. We have focused on ultrasonic soldering technology more than 20 years. The ultrasonic technology and automated system are researched and developed all by ourselves. In our sample and testing studio we are offering the testing of your material. According to the needs and testing result, Cheersonic would customize ultrasonic solutions for you.