Ultrasonic Surface Treatment Of Non-Woven Fabric

Ultrasonic surface treatment of non-woven fabric-cheersonic

In the rapid development process of materials science and engineering, non-woven fabrics, with their unique structure and properties, are widely used in many fields such as medical and health care, filtration, and packaging. With the continuous innovation of technology, the surface treatment process of non-woven fabrics is also constantly upgrading. Among them, the ultrasonic spraying technology of non-woven fabrics, with its outstanding performance and innovation, is gradually becoming the focus of industry attention, ushering in a new era of material surface treatment.

In the current pursuit of sustainable development, ultrasonic spraying technology has demonstrated strong energy-saving advantages in the field of non-woven fabric treatment. Compared with traditional spraying techniques, ultrasonic spraying has a higher utilization rate of coatings. Because the atomized particles it generates are fine and uniform, they can adhere more effectively to the surface of non-woven fabrics, reducing the scattering and waste of coatings during the spraying process. Meanwhile, ultrasonic spraying does not require a large amount of compressed air or high-pressure equipment, which greatly reduces energy consumption. In terms of environmental protection, this technology reduces the waste of coatings, which means a reduction in the emission of volatile organic compounds, meeting today’s strict environmental protection requirements.

Ultrasonic spraying technology endows non-woven fabrics with diverse functional characteristics, greatly expanding their application boundaries. In the medical and health field, through ultrasonic spraying of antibacterial agents or antiviral coatings, non-woven fabrics can be endowed with highly efficient antibacterial and antiviral properties, which can be used to make medical masks, surgical gowns, medical dressings, etc., effectively reducing the risk of cross-infection. In the field of filtration, spraying functional nanomaterials can enhance the filtration efficiency and selectivity of non-woven fabrics, enabling them to play a more outstanding role in air purification, water filtration and other aspects. In the field of new energy, conductive materials can be sprayed onto non-woven fabrics by ultrasonic waves to prepare high-performance electrode materials, which can be applied to lithium-ion batteries, supercapacitors, etc., providing support for the development of the new energy industry. In addition, in fields such as clothing and automotive interiors, ultrasonic spraying technology can also endow non-woven fabrics with special functions such as water resistance, oil resistance, and stain resistance, meeting the diverse needs of different industries.

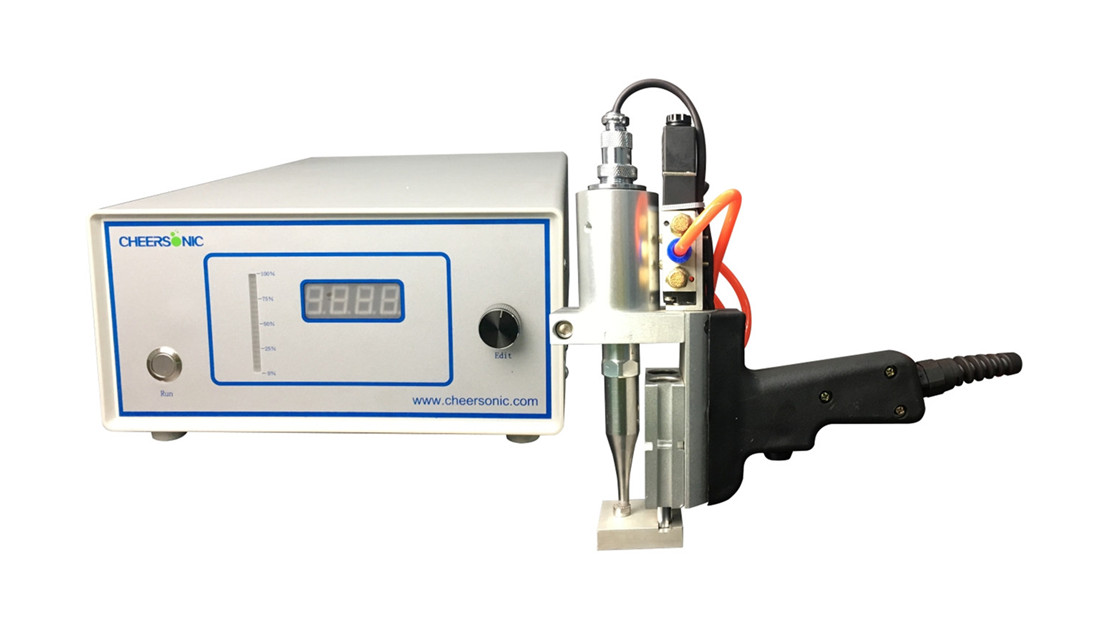

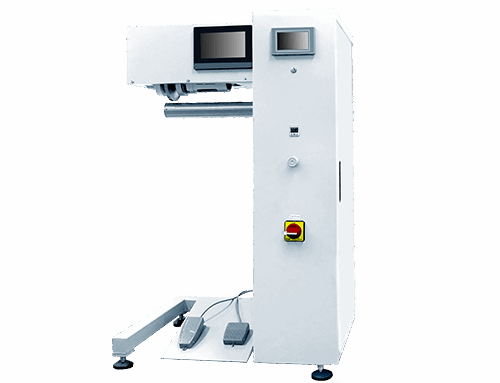

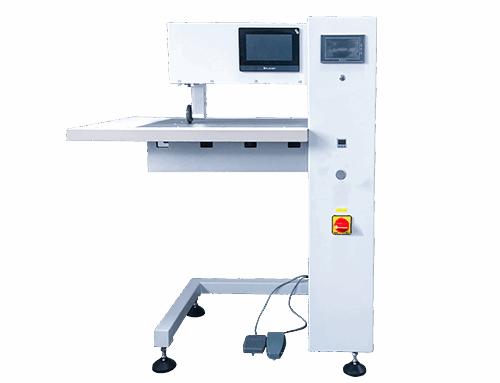

With the continuous advancement of technology, the ultrasonic spraying technology of non-woven fabrics is also constantly innovating and improving. On the one hand, researchers are constantly exploring new coating formulations and spraying processes to further enhance the performance and functionality of non-woven fabrics. On the other hand, intelligent and automated ultrasonic spraying equipment has gradually been applied in production practice, enhancing production efficiency and the stability of product quality. In the future, with the deep integration of nanotechnology, new materials technology and ultrasonic spraying technology, non-woven fabrics will be endowed with more unprecedented characteristics and show greater application potential in high-end manufacturing, aerospace, biomedicine and other fields.

In the future development, this technology is expected to continuously break through and innovate, driving the non-woven fabric industry to a higher stage of development and providing more high-quality and high-performance material support for the development of various fields.