Ultrasonic Sewing Fabric-aviation Insulation Panels

Ultrasonic Sewing Fabric-aviation Insulation Panels – Cheersonic

Acoustic for ceilings for partition walls.Panels composed of several layers of insulating materials. Their function: reducing the level of noise generated by the engines and flight conditions; maintaining the interior temperature .The aviation and space industry has strict requirements on the weight and volume of the thermal insulation materials used, and often requires them to have sound insulation, vibration reduction, anti-corrosion and other properties. The requirements for insulation materials vary among various aircraft. Foamed plastic, ultra-fine glass wool, high silicon oxygen cotton and vacuum heat insulation board are commonly used in aircraft cockpit and cockpit for heat insulation.

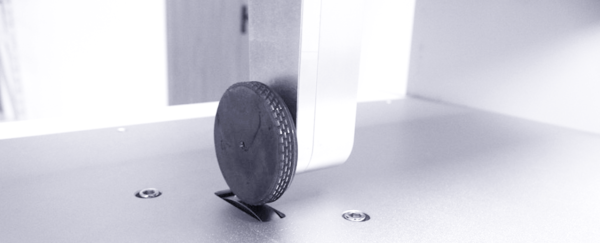

Ultrasonic aviation insulation panels welding offers some key advantages over other forms of welding: It saves time. It is much faster than traditional welding methods, as virtually no time is needed for drying or curing. It is a highly automated process, which also saves on manpower and helps you get the parts you need faste. Ultrasonic welding has some advantages ,such as high precision, low cost , high speed and it produces very little noise, performed without any lubrication and doesn’t use chemicals in its process.These machines are highly versatile so they can be easily modified for different applications such as cutting glass, plastic, ceramics, etc.

Cheersonic has focused on the technologies of ultrasonics and automations for more than 20 years, and supply a series of standard ultrasonic sewing machine as well as bespoke ultrasonic sewing solutions for different industries, such as automotive, hygiene and medical, filtration, industrial safety and so on. Our factory is strictly in terms of ISO9001 manufacturing the high quality & reliable ultrasonic machines.