Ultrasonic Bed Cover Welding

The bed cover is a kind of brocade silk fabric, with magnificent colors, fine patterns, and national characteristics. It is a high-grade bed cover. The crepe bed cover, also known as the seersucker bed cover, is made of woven color striped seersucker, which is soft to the touch. The tufted bed cover, also known as the embroidered bed cover, can be made of pure cotton, acrylic fiber, polypropylene fiber, etc., and the colored yarn is fixed on the base fabric with a tufting machine, and a certain length of velvet is formed on the back of the base fabric, and then it is drawn on the back of the base fabric. The pattern on the base fabric is repeatedly tufted, and then finished by seaming and brushing. Wet finishing can also be carried out to avoid napping. The seam finishing of the tufted bed cover is to use multi-strand thread to lock the edges on all sides, and then decorate the three sides of the bed cover with beards. The color of the beards should be consistent with the basic color of the bed cover. The cotton-lined bed cover is composed of a quilt cover, a lining and a filler (chemical fiber flakes), which are sewn into a thin quilt cover, which is light, soft and slippery. The pattern design of the bed cover is planned and grasped according to the furnishings and colors of the whole room.

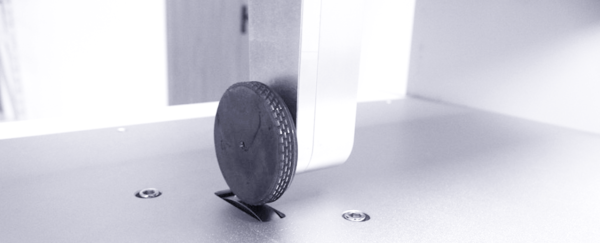

Ultrasonic bed cover welding offers some key advantages over other forms of welding: It saves time. It is much faster than traditional welding methods, as virtually no time is needed for drying or curing. It is a highly automated process, which also saves on manpower and helps you get the parts you need faste. Ultrasonic bed cover welding has some advantages, such as high precision, low cost , high speed and it produces very little noise, performed without any lubrication and doesn’t use chemicals in its process. These machines are highly versatile so they can be easily modified for different applications such as cutting glass, plastic, ceramics, etc.

Cheersonic has focused on the technologies of ultrasonics and automations for more than 20 years, and supply a series of standard ultrasonic sewing machine as well as bespoke ultrasonic sewing solutions for different industries, such as automotive, hygiene and medical, filtration, industrial safety and so on. Our factory is strictly in terms of ISO9001 manufacturing the high quality & reliable ultrasonic machines.