The intelligent core for innovating textile technology

The intelligent core for innovating textile technology-cheersonic

In the wave of upgrading towards automation and precision in the textile industry, ultrasonic sewing machine cores, as a disruptive technology, are redefining the boundaries of traditional sewing techniques. This innovative technology that integrates acoustics, materials science and intelligent control, with advantages such as non-contact processing and high efficiency and precision, has become a core enabling tool in fields such as clothing manufacturing, home textiles and industrial fabrics.

Traditional sewing techniques inevitably leave pinholes, which may cause the fabric to seep water, become breathable or break. The ultrasonic sewing machine core forms continuous and dense seams on the fabric surface through melt welding technology, completely eliminating the risk of pinholes. For instance, in the waterproof gluing process of outdoor windbreakers, this technology can increase the waterproof index at the seams to over 20,000mm, while maintaining the softness and breathability of the fabric, and taking into account both functionality and wearing experience.

Traditional cutting techniques are prone to causing frayed edges and stringing at the fabric edges, while ultrasonic cutting can complete the melting in an instant and simultaneously perform heat sealing treatment on the edges. Take medical non-woven fabric products (such as surgical gowns and masks) as an example. The edge flatness error of ultrasonic cutting is less than 0.1mm, and there is no need for subsequent edging processes. The production efficiency is increased by more than 50%, and at the same time, it avoids the risk of fiber shedding that may be caused by traditional needles and threads, meeting the requirements of medical-grade cleanliness.

In addition to welding and cutting, the ultrasonic sewing machine core can also imprint complex patterns, logos or three-dimensional designs on the fabric surface by replacing the welding heads with different textures. This process does not require ink or chemical additives. It achieves decorative effects through physical deformation, which is both environmentally friendly and can increase the added value of products. It is widely used in high-end fashion, home textiles and other fields.

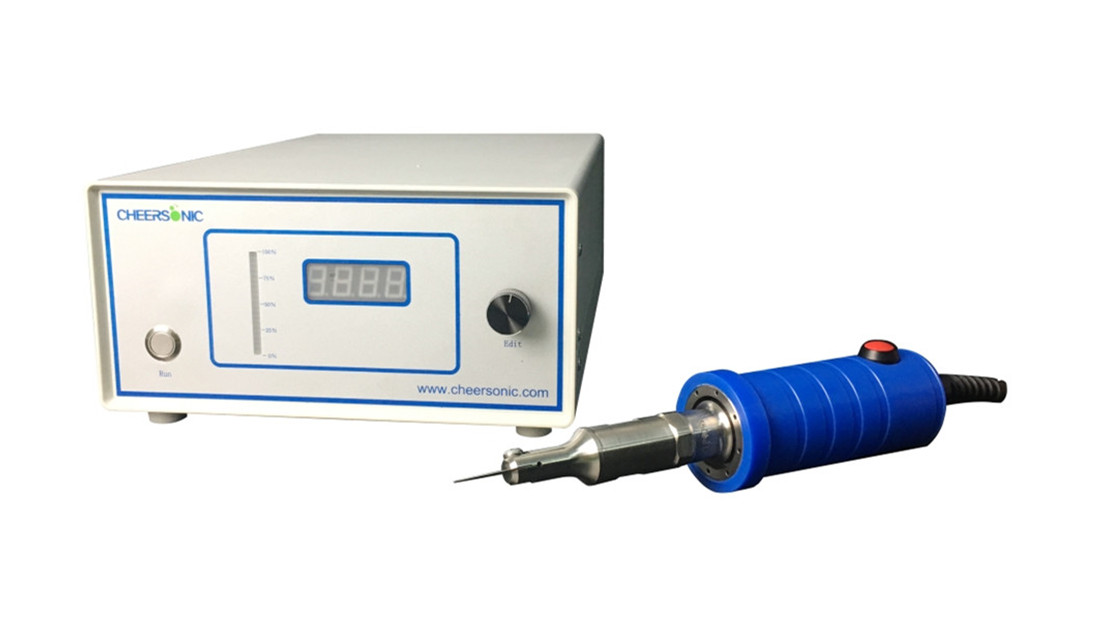

ultrasonic sewing machine cores have gradually integrated intelligent control systems, which monitor parameters such as welding temperature, pressure and speed in real time through sensors, and automatically optimize the process plan in combination with AI algorithms. For instance, in mass production, the system can dynamically adjust the vibration frequency and duration of action based on subtle changes in fabric thickness and material, ensuring consistent processing quality for each product. In addition, the modular design enables it to be seamlessly integrated into automated production lines and interact with robots, visual inspection equipment, etc., to build a highly intelligent textile manufacturing system.

With the development of new material technology, ultrasonic sewing machine cores will further expand their application boundaries. For example, for new materials such as nanofibers and smart color-changing fabrics, their high-frequency vibration processing characteristics can achieve more precise structural control; In the medical field, by combining biodegradable materials, this technology is expected to develop absorbable alternatives to surgical sutures. In the future, with the deepening of the concepts of green manufacturing and intelligent manufacturing, ultrasonic sewing machine cores will become the core engine for the low-carbon and high-end development of the textile industry, accelerating the leap from “Made in China” to “Intelligently Made in China”.