Project Description

Ultrasonic Jackets sewing

Outdoor jacket is one of the important outdoor sports equipment. In the outdoor protective clothing is the first barrier to protect the body, it can protect outdoor climbers avoid contact with moisture, keep the body dry, keep the body temperature is not too low, maintain good permeability.

High demand functional outdoor jackets, the drawbacks of using the traditional needlework sewing is the phenomenon of pinhole sewing off, leakage and so on, long-term outdoor sun and rain easily degummed, and low aesthetic.

Ultrasonic technology truly seamless sewing, to eliminate off-line, degumming, leaking and so on.

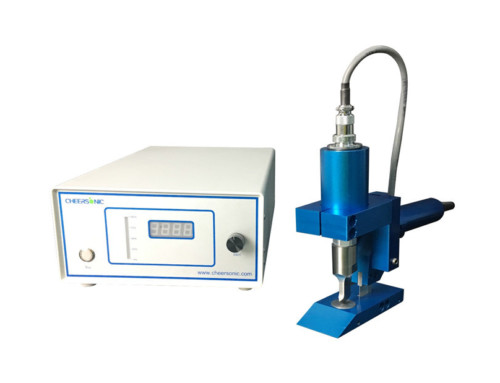

CHEERSONIC ultrasonic seamless sewing equipment process is the principle of the two fabrics through a professional ultrasonic equipment to be integrated. When 20000 times per second ultrasonic vibration through the sewing tool head role in the two fabrics at the interface, due to friction caused by high frequency vibration, the interface fabric quickly melt seal.

CHEERSONIC Guarantee:

No damage and burrs

No burns and hot fabric

No toxic smoke emissions

No sewing needle

Less energy consumption

Better aesthetics

Better sealing

Better environmental protection

Written by Alisa Yu